PRODUCT > Leak Detector

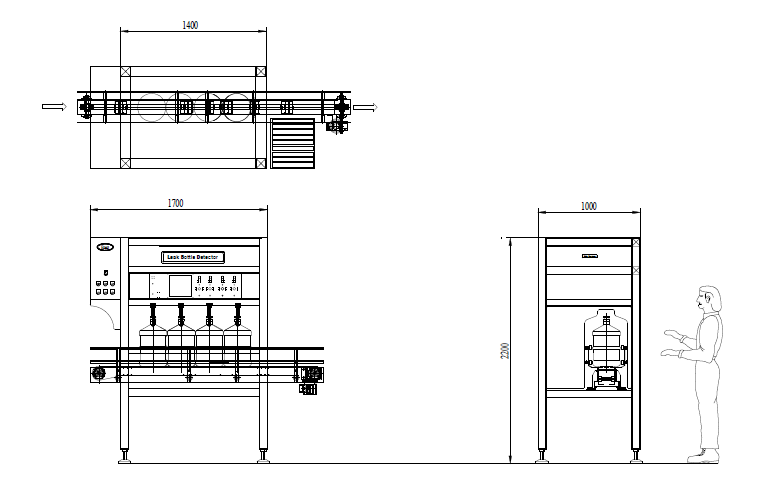

Leak Detector Machine

Definition

All kinds of leaks (small hole, incontinence, spout breakage, etc.)

can be detected.

Specifications

- Capacity: up to 3000bph

- Minimum detection hole:0.45mm

- Sensing Time: 2sec(Adjustable)

- Voltage: 380V – 450V/220V, 50/60Hz

- Air: 5~6Kg/cm2

- Pneumatic components TPC

- Motor and gear box: MOTOVARIO

- Electronic components: LS (LG Brand)

Features

- Fully automatic operation

- Auto Rejection

- Accurate & Reliable detection

- Powerful PLC controller

- No-bottle mechanical stress

- Easy to set-up and operate