PRODUCT > SEMI-AUTO HIGH PRESSURE BOTTLE WASHER

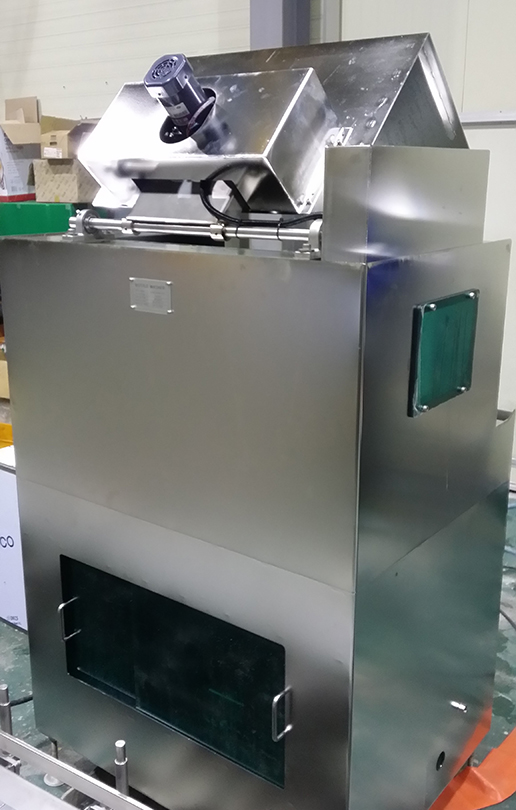

SEMI-AUTO HIGH PRESSURE BOTTLE WASHER

Our manual washer is designed for nozzle spraying with

very powerful high pressure of 100Kg(bar).

Wash all areas inside and outside the bottle.

All contaminants can be removed with up to 99% efficiency.

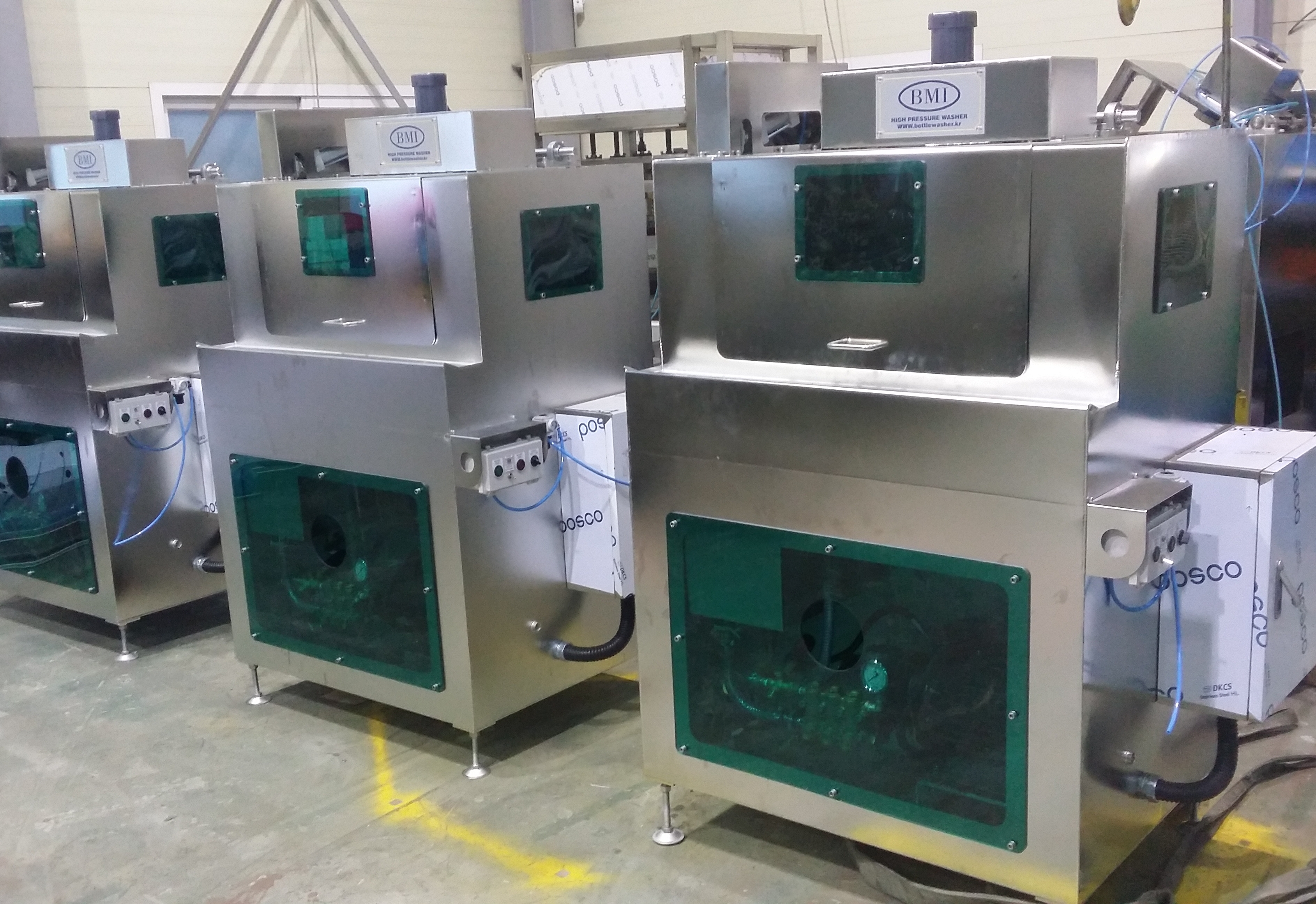

MW-2(Internal & External washing)

MW-2(Internal washing only)

MW-1(Internal & External washing)

Specification

- Air – 5Kg/cm2

- Using 2 Ways High Pressure Jet Nozzles up and down

- Washing Time: 12 sec/Bottle(Adjustable)

- Washing Capacity: 200BPHcapacities

- Tank Storage: 20L

- Motor Output: 10HP

- Pump Output: 80BAR ~

- Voltage: 380V – 450V/220V, 50/60Hz

- All stainless steel construction(S.S. 304 )

- Semi-Automatic bottles loading and unloading

Advantages

- Controlled this machine by control panel

- Low water consumption washer design

- Easy maintaining and safety design

| Model Name | MW-1 | MW-2 | MWT-1 |

|---|---|---|---|

| Capacity(BPH) | 100 | 200 | 60 |

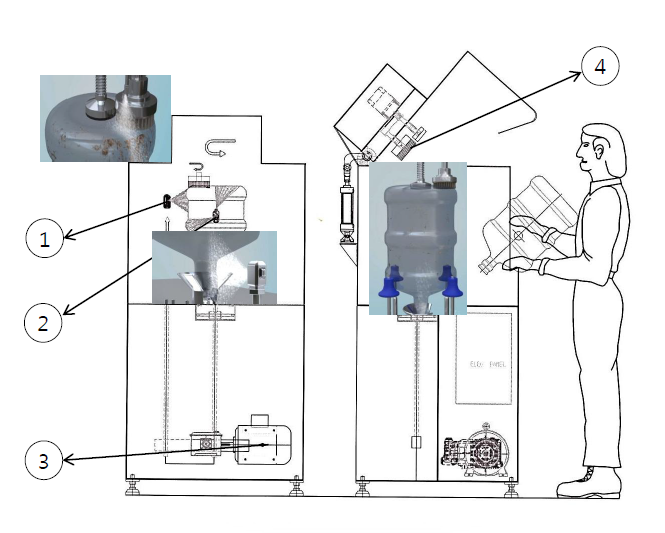

LAY-OUT (SEMI-AUTO)

- Bottle outside washing nozzle

- Bottle inside washing nozzle

- High Pressure pump

- Bottle outside washing brush

SEMI-AUTO MWT WASHER

(Washing Rinse Filling Capping)

• The machine is semi-automatic, high pressure of 60 Kg (bar), external and internal washing of bottles.

• Also, after washing, rinsing, filling, and capping can all be done at the same time.

• The production capacity of this unit is 60bph.

Specification

- Air – 5Kg/cm2

- Using 2 Ways High Pressure Jet Nozzles up and down

- Washing Time: 12 sec/Bottle(Adjustable)

- Washing Capacity: 200BPHcapacities

- Tank Storage: 20L

- Motor Output: 10HP

- Pump Output: 80BAR ~

- Voltage: 380V – 450V/220V, 50/60Hz

- All stainless steel construction(S.S. 304 )

- Semi-Automatic bottles loading and unloading

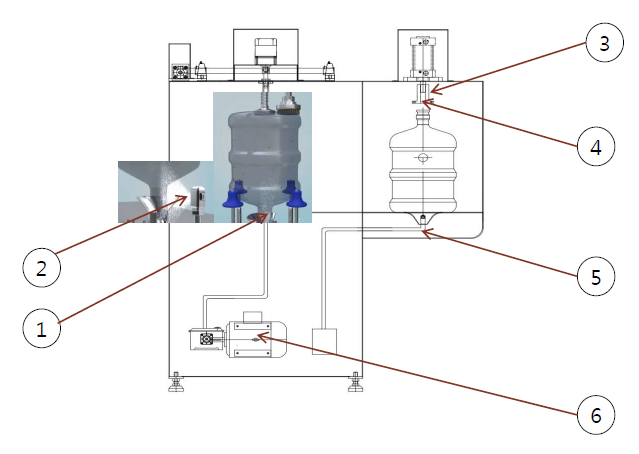

LAY-OUT

- High-pressure washing inside bottles (use of washing agents and chemicals)

- High pressure washing outside the bottle

- Filling

- Capping

- Rinsing

- High pressure pump

MWT-1