PRODUCT > SNIFFER (ODOR DETECTOR)

SNIFFER (ODOR DETECTOR)

Definition

Using the sense of human smell to detect contaminants in reused water bottles has its limitations.To address this issue, a machine-based system has been developed to automatically detect and classify contaminants. This system is designed using high-performance odor detection sensors, allowing for accurate and rapid detection and treatment of contaminated bottles. Furthermore, with the use of specially designed detection systems, the accuracy of the system has been further improved.

By automating the process of reused water bottle detection, this technology can replace human labor, resulting in a safer and more efficient production process. Additionally, this can reduce the amount of contaminants produced during the manufacturing process, leading to a more environmentally friendly manufacturing process. Ultimately, this technology can improve product quality, increase productivity, and improve working conditions.

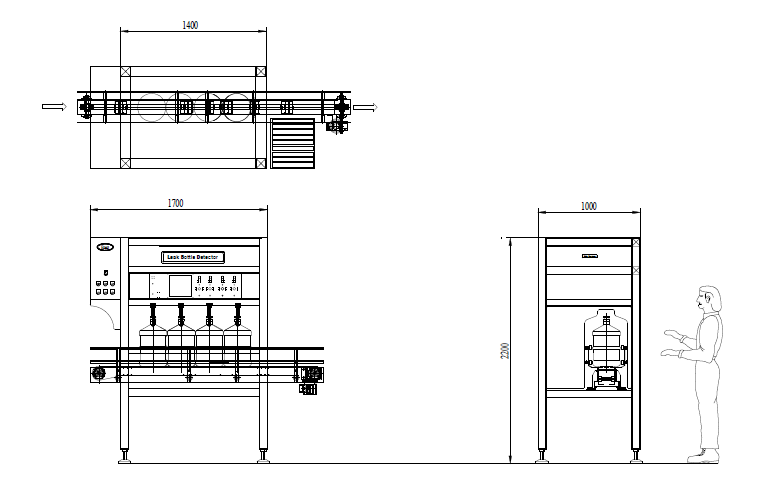

Configuration

- Automatic Processing

- Processing time : 3 Sec./Bottle

- Capacity: 300 ~ 3000 BPH

- Motor Output : 1HP

- Voltage: 380V – 450V/220V, 50/60Hz

- Air-5Kg/cm2

Advantages

Odor Detection System for BottlesThis specially designed odor detection system detects only theodors (gases) inside the water bottle.The sensitivity of odor detection can be adjusted to 10 levels of strong/weak to meet user’s quality standards.

ODM(Odor detecting machine) detects contaminants such as:

- -Ethyl acetate: VOC(Volatile organic compound) that causes all kinds of smells when cooking or from construction materials

- -Hydrogen sulfide

- -Ammonia, acetaldehyde

- -Ethanol(alcohol), gasoline, diesel, benzene, engine oil, kerosene, etc.

- -Solvents: Acetone, toluene, etc.

- -Garlic, kimchi, vineger, etc.

- -Soft drinks, fermented fruits, juice, beer, wine,

- -Cleaners, detergents

- -It detects a different types of odor than commom odor inside the bottles.

| Model Name | ODM-2 | ODM-3 | ODM-4 | ODM-6 | ODM-8 | ODM-10 |

|---|---|---|---|---|---|---|

| No. of Head | 2 | 3 | 4 | 6 | 8 | 10 |

| Capacity(BPH) | 800 | 1200 | 1500 | 2000 | 2500 | 3000 |

PRODUCT SPECIFICATIONS

| GENERAL | |

|---|---|

| Product Name | Odor Detector Machine(Sniffer) |

| Model Name | ODM |

| Applicable Bottle Size | 3,4 & 5 Gallon bottles (11, 13, 15 & 19 liters) |

| Automatic Grade | Automatic |

| Product Description | Automatic Odor Detecting Machine |

| Structure Type | Linear |

| Material | SS304,SS316Stainless Steel by argon welding |

| Warranty | Two Years |